Our Trusted Partners

Provides reliability and condition-based monitoring systems (electrical & mechanical), energy management, valves, pumps, gas‑phase filtration systems, and technical services. Represents global manufacturers and offers in-house and outsourced services such as thermal scanning and electrical preventive maintenance. Also conducts training and certification courses

Infrared Thermography Services refer to the professional use of infrared (IR) cameras to detect and visualize heat patterns and temperature variations on surfaces. This non-contact, non-destructive testing technique helps identify issues that are not visible to the naked eye, often before they cause serious problems.

Ultrasonic Testing (UT), this is a non-destructive testing (NDT) method used to detect flaws, measure material thickness, or monitor equipment health. Industrial ultrasound uses high-frequency sound waves (typically 0.5 to 25 MHz) that are transmitted into materials. When these waves encounter a boundary (like a crack, void, or the back wall of the material), part of the wave reflects back. T

Vibration Analysis Services involve monitoring and analyzing the vibration patterns of machinery or structures to detect imbalances, misalignments, looseness, or mechanical faults before they lead to failures. It is a key part of predictive maintenance and reliability-centered maintenance (RCM).

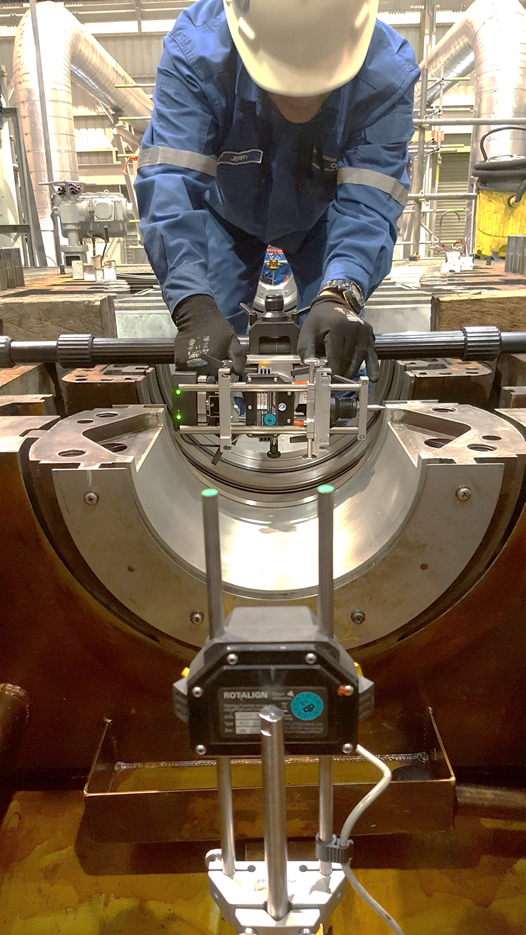

Laser Shaft Alignment Services involve the precise alignment of rotating machinery shafts using laser measurement tools to ensure optimal performance, reduced wear, and minimal energy loss. Misalignment is one of the most common causes of machinery failure, and laser alignment is the most accurate and efficient method to correct it.

Partial discharge is a localized electrical discharge that partially bridges the insulation between conductors or between a conductor and ground. It occurs in high-voltage equipment when insulation becomes weak due to age, moisture, contamination, or manufacturing defects.

Industrial Repair and Calibration Services ensure that equipment, instruments, and systems operate reliably, safely, and within required tolerances. These services support a wide range of industries including manufacturing, energy, utilities, aerospace, pharmaceuticals, food processing, and more.

SSC certifications validate foundational and advanced skills in predictive maintenance, condition monitoring, and non-destructive testing (NDT) techniques for industrial applications.

This Non-Certification outlines completed training in essential Condition Monitoring and Non-Destructive Testing (NDT) techniques, enabling early detection of faults, enhanced asset reliability, and predictive maintenance execution.